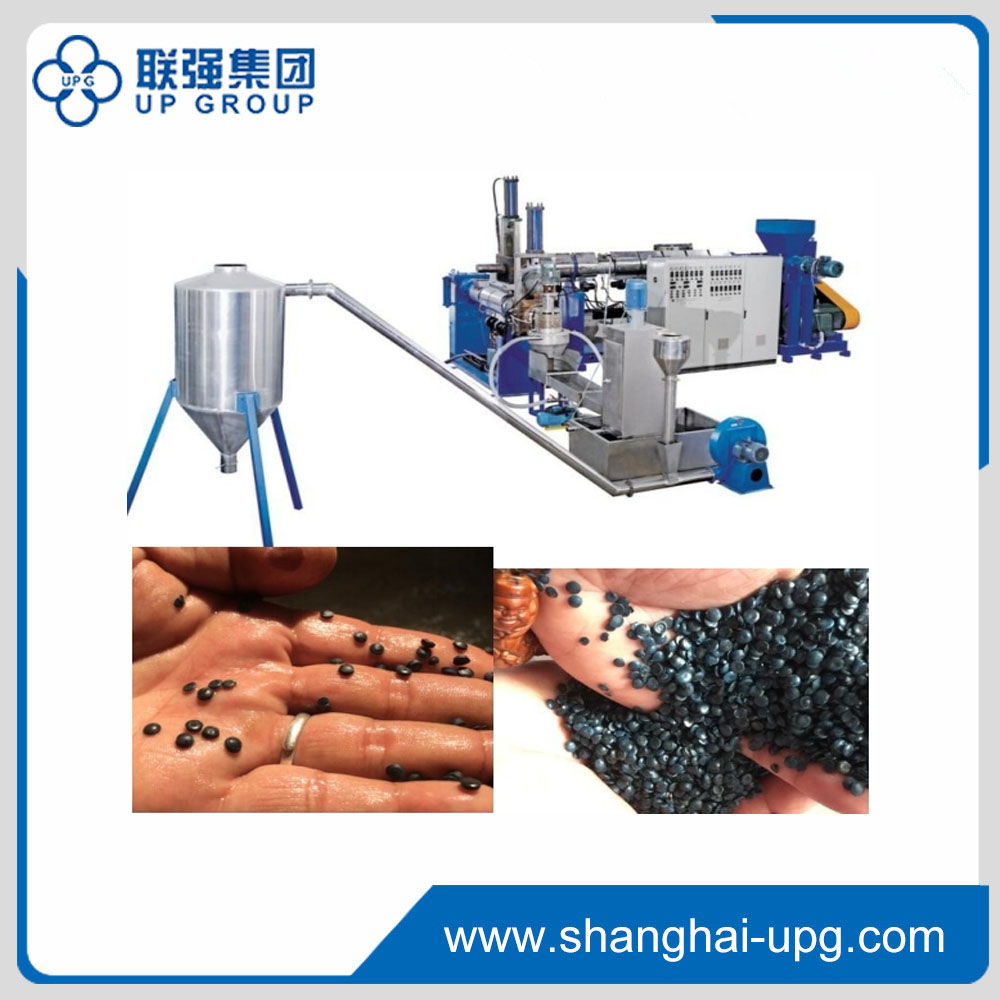

China Wholesale Filler Granulating Machine Manufacturers – LQ150-200 PE Film double-stage pelletizing line – UP Group Detail:

Detail parameter:

Belt conveyor

1.Effective width: 600mm

2.Motor power: 1.5KW

Agglomeration room

1.Motor power: 45KW 2.Total Volume: 200L

3.Effective volume:150L 4.Rotary blade: 9

5.Fixed blade: 12 6.Blades rotation speed: 900RPM

LQ-SJ85/28 Extruder

Driving motor:55 KW, AC motor(SIMENS China)

Screw:Diameter of screw: 85mm, L/D: 28/1

Material of screw: 38CrMoAl Surface treatment: Nitriding processing

Barrel:Inner processing: nitride

Heating power: 55KW Cooling air fans: 0.37KWx5 sets

Gear box: Special hard gear reducer

Venting system:Vacuum pump: 2.2KWx1set

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Changing screen time≤2 sec

Screen diameter: 200mm

Motor power: 1.5 KW

LQ-SJ85/10 Extruder

Driving motor: 22 KW, AC motor(SIMENS China)

Screw :

Diameter of screw: 85mm, L/D: 10/1

Material of screw: 38CrMoAl

Surface treatment: Nitriding processing

Barrel: Heating power: 22KW Cooling air fans: 0.72KW

Gear box: Special hard gear reducer

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

1.Motor power: 1.1 KW

2.Water pump power: 3 KW

3.Blade: 2-4 pcs

4.Part contact with water is made of stainless steel (S.S.)

Conveying channel & water tank

Basic material of channel & tank body:

stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

Loading power:

Motor power: 3 KW, conveying pipeline: S.S

Silo:

Material of storage silo: S.S; Silo frame: Carbon steel

Volume of silo: 500L

Electric Controller

Electronic control components(including

circuit breakers, AC contactor, button, indicator light.)

Temperature controller: OMRON

Contractor: SIEMENS

Other: DELIXI

Product detail pictures:

Related Product Guide:

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for China Wholesale Filler Granulating Machine Manufacturers – LQ150-200 PE Film double-stage pelletizing line – UP Group, The product will supply to all over the world, such as: New York, Accra, Dominica, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

-

China Wholesale Granulator Machine For Plastic ...

-

China Wholesale 100w Co2 Laser Manufacturers &#...

-

China Wholesale Guillotine Shear Factory –...

-

China Wholesale Injection Blow Molding Manufact...

-

China Wholesale Nylon Printing Machine Supplier...

-

China Wholesale Plastic Pvc Cold Strand Granula...