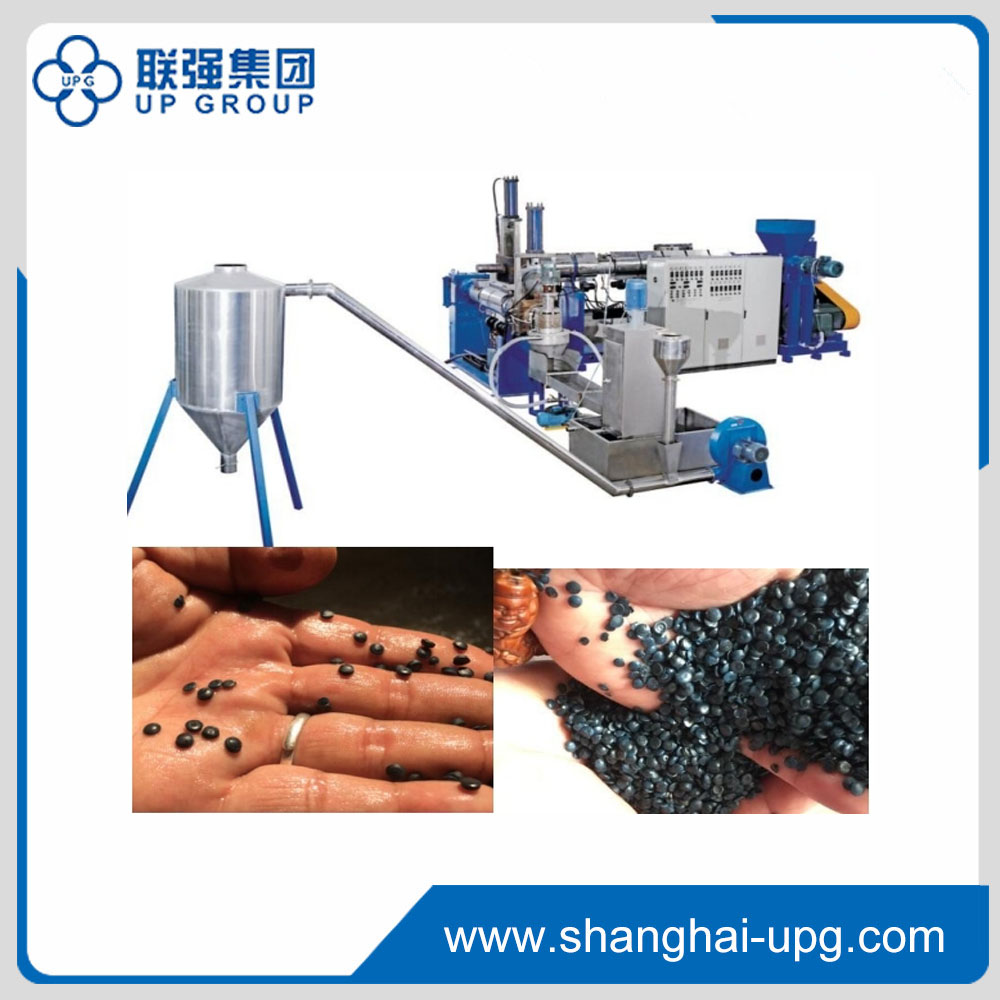

China Wholesale home vacuum former Suppliers – LQ250-300PE Film double-stage pelletizing line – UP Group Detail:

Detail parameter

Belt conveyor

1.Effective width: 600mm

2.Motor power: 1.5KW

Agglomeration room

1.Motor power: 45KW 2.Total Volume: 200L

3.Effective volume:150L 4.Rotary blade: 9

5.Fixed blade: 12 6.Blades rotation speed: 900RPM

LQ-SJ85/28 Extruder

Driving motor:55 KW, AC motor(SIMENS China)

Screw:Diameter of screw: 85mm, L/D: 28/1

Material of screw: 38CrMoAl Surface treatment: Nitriding processing

Barrel:Inner processing: nitride

Heating power: 55KW Cooling air fans: 0.37KWx5 sets

Gear box: Special hard gear reducer

Venting system:Vacuum pump: 2.2KWx1set

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Changing screen time≤2 sec

Screen diameter: 200mm

Motor power: 1.5 KW

LQ-SJ85/10 Extruder

Driving motor: 22 KW, AC motor(SIMENS China)

Screw :

Diameter of screw: 85mm, L/D: 10/1

Material of screw: 38CrMoAl

Surface treatment: Nitriding processing

Barrel: Heating power: 22KW Cooling air fans: 0.72KW

Gear box: Special hard gear reducer

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

1.Motor power: 1.1 KW

2.Water pump power: 3 KW

3.Blade: 2-4 pcs

4.Part contact with water is made of stainless steel (S.S.)

Conveying channel & water tank

Basic material of channel & tank body:

stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

Loading power:

Motor power: 3 KW, conveying pipeline: S.S

Silo:

Material of storage silo: S.S; Silo frame: Carbon steel

Volume of silo: 500L

Electric Controller

Electronic control components(including

circuit breakers, AC contactor, button, indicator light.)

Temperature controller: OMRON

Contractor: SIEMENS

Other: DELIXI

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for China Wholesale home vacuum former Suppliers – LQ250-300PE Film double-stage pelletizing line – UP Group, The product will supply to all over the world, such as: Canada, Mauritania, Ethiopia, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!