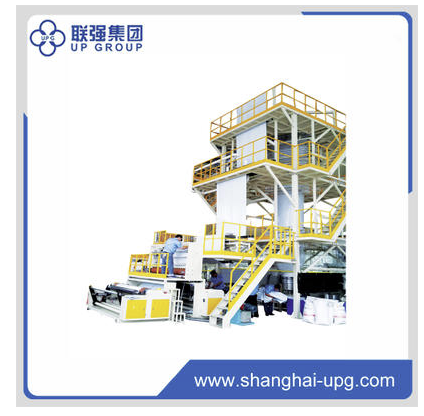

China Wholesale Most Common Injection Molded Plastic Manufacturers – LQ5L-1800 Five-layer co-extrusion film blowing machine – UP Group Detail:

Product Description

- Introduction

- This model is designed for pressing and packaging meterials with higher rebound force including rigid plastics. PET bottles,hay, sponges,cloths and others.

- Heavy-duty vertical hydraulic baler with double-cylinder balance compressing design, and extraordinary hydrau-lic system to provide continuous stable force during compression. It generates greater compression force to bale larger loads. four sides opening style with”#” shape strapping capability, also allows the materials to be packaged before strapping. Chamber anti-rebound device can be optionally installed.

Specification

|

Model |

Hydraulic Power |

Bale Size (L*W*H)mm |

Feed Opening Size(L*H)mm |

Chamber Size (L*W*H)mm |

Output (Bales/hr) |

Power (Kw/Hp) |

Machine Size (L*W*H)mm |

Machine Weight(Kg) |

|

LQA070T80 |

80 |

1000*700*(500-900) |

1000*500 |

1000*700*1500 |

4-6 |

11/15 |

1800*1480*3500 |

2600 |

|

LQA070T120 |

120 |

1000*700*(500-900) |

1000*500 |

1000*700*1500 |

4-6 |

15/20 |

2100*1700*3500 |

3200 |

|

LQA1010T160 |

160 |

1100*1000*(400-1200) |

1100*800 |

1100*1000*2000 |

4-6 |

30/40 |

2100*1800*4600 |

7300 |

Main Configuration

- Extruder

1.1 Screw diameter: 65; 55; 65; 55;65

1.2 L/D ratio: 30:1

1.3 Max screw speed:100r/min

1.4 Screw Structure: Mixed type, with barrier

1.5 Screw and Barrier material: 38CrMoAl, Bi-metallic

1.6 Heater type: ceramic heater.

1.7 Temperature Control: 5 zone; 4zone; 5 zone;4 zones;5 zones

1.8 Barrel Heater power: 60kw

1.9 Main motor: 37KW;30kw; 37kw; 30kw;37KW. (SIEMENS BEIDE)

1.10 Inverter: 37KW;30kw; 37kw; 30kw;37KW. (SINEE)

1.11 Gear box size: A: 200#, B: 180#, C: 200#,D: 180#, E: 200# (SHANDONG WUKUN)

1.11 Screen Changer: hydraulic screen changer: 5 sets

- Die head

2.1 Die head type: A+B+C+D+E fixed IBC type die head.

2.2 Die head material: Alloy steel forging and heat treatment;

2.3 Die head width: ◎400mm

2.4 Channel and surface hard chromium plating

2.5 Heater: Aluminum ceramics heater.

- Cooling Device (with IBC system)

3.1 Type: 800mm double lips air ring

3.2 Material: cast aluminum.

3.3 Main Air blower: 11 kw:

3.4 Film bubble cold air exchange device; Hot air channel and cold air channel mutual independence

3.5 Film Bubble monitor sensor: Import ultrasound Probe (3 sets), Controlling the film bubble size.

3.6 Inlet air blower: 7.5kw

3.7 Outlet air blower: 7.5kw

3.8 Automatic wind, automatic air suction

- Bubble Stabilizing frame

4.1 Structure: Circular type

- Collapsing Frame & Gusset board

5.1 Material: Steel structure frame with special material

5.2 Adjusting mode:manual

- Haul-off Ocillation Traction System

6.1 Traction roller: 1800mm

6.2 Effective film width: 1600mm

6.3 Traction Motor power: 4.5kw (adjust by inverter) three-phase asynchronous motor

6.4 Traction speed: 70m/min

6.5 Up traction rotating motor: 4.5kw (adjust by inverter)

6.6 Down traction motor: 4.5kw (adjust by inverter)

6.7 Moving of the roll is driven by pneumatic

6.8 Traction roller material: Ethylene-Propylene-Diene Monomer

6.9 EPC Edge correction system

- Trimming device

7.1 Middle Section: 3 pcs

7.2 Edge Section device: 2 pcs

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for China Wholesale Most Common Injection Molded Plastic Manufacturers – LQ5L-1800 Five-layer co-extrusion film blowing machine – UP Group, The product will supply to all over the world, such as: Jordan, United States, French, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

-

China Wholesale Injection Molding Press Manufac...

-

China Wholesale Toy Molding Machine Manufacture...

-

China Wholesale Stencil Printing Machine Suppli...

-

China Wholesale Slitting And Winding Machine Ma...

-

China Wholesale Single Screw Extruder Manufactu...

-

China Wholesale Machine Plastic Injection Facto...