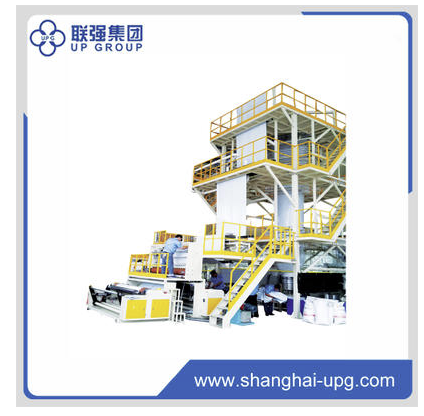

China Wholesale Pet Bottle Manufacturing Machine Factories – LQ5L-1800 Five-layer co-extrusion film blowing machine – UP Group Detail:

Product Description

- Introduction

- This model is designed for pressing and packaging meterials with higher rebound force including rigid plastics. PET bottles,hay, sponges,cloths and others.

- Heavy-duty vertical hydraulic baler with double-cylinder balance compressing design, and extraordinary hydrau-lic system to provide continuous stable force during compression. It generates greater compression force to bale larger loads. four sides opening style with”#” shape strapping capability, also allows the materials to be packaged before strapping. Chamber anti-rebound device can be optionally installed.

Specification

|

Model |

Hydraulic Power |

Bale Size (L*W*H)mm |

Feed Opening Size(L*H)mm |

Chamber Size (L*W*H)mm |

Output (Bales/hr) |

Power (Kw/Hp) |

Machine Size (L*W*H)mm |

Machine Weight(Kg) |

|

LQA070T80 |

80 |

1000*700*(500-900) |

1000*500 |

1000*700*1500 |

4-6 |

11/15 |

1800*1480*3500 |

2600 |

|

LQA070T120 |

120 |

1000*700*(500-900) |

1000*500 |

1000*700*1500 |

4-6 |

15/20 |

2100*1700*3500 |

3200 |

|

LQA1010T160 |

160 |

1100*1000*(400-1200) |

1100*800 |

1100*1000*2000 |

4-6 |

30/40 |

2100*1800*4600 |

7300 |

Main Configuration

- Extruder

1.1 Screw diameter: 65; 55; 65; 55;65

1.2 L/D ratio: 30:1

1.3 Max screw speed:100r/min

1.4 Screw Structure: Mixed type, with barrier

1.5 Screw and Barrier material: 38CrMoAl, Bi-metallic

1.6 Heater type: ceramic heater.

1.7 Temperature Control: 5 zone; 4zone; 5 zone;4 zones;5 zones

1.8 Barrel Heater power: 60kw

1.9 Main motor: 37KW;30kw; 37kw; 30kw;37KW. (SIEMENS BEIDE)

1.10 Inverter: 37KW;30kw; 37kw; 30kw;37KW. (SINEE)

1.11 Gear box size: A: 200#, B: 180#, C: 200#,D: 180#, E: 200# (SHANDONG WUKUN)

1.11 Screen Changer: hydraulic screen changer: 5 sets

- Die head

2.1 Die head type: A+B+C+D+E fixed IBC type die head.

2.2 Die head material: Alloy steel forging and heat treatment;

2.3 Die head width: ◎400mm

2.4 Channel and surface hard chromium plating

2.5 Heater: Aluminum ceramics heater.

- Cooling Device (with IBC system)

3.1 Type: 800mm double lips air ring

3.2 Material: cast aluminum.

3.3 Main Air blower: 11 kw:

3.4 Film bubble cold air exchange device; Hot air channel and cold air channel mutual independence

3.5 Film Bubble monitor sensor: Import ultrasound Probe (3 sets), Controlling the film bubble size.

3.6 Inlet air blower: 7.5kw

3.7 Outlet air blower: 7.5kw

3.8 Automatic wind, automatic air suction

- Bubble Stabilizing frame

4.1 Structure: Circular type

- Collapsing Frame & Gusset board

5.1 Material: Steel structure frame with special material

5.2 Adjusting mode:manual

- Haul-off Ocillation Traction System

6.1 Traction roller: 1800mm

6.2 Effective film width: 1600mm

6.3 Traction Motor power: 4.5kw (adjust by inverter) three-phase asynchronous motor

6.4 Traction speed: 70m/min

6.5 Up traction rotating motor: 4.5kw (adjust by inverter)

6.6 Down traction motor: 4.5kw (adjust by inverter)

6.7 Moving of the roll is driven by pneumatic

6.8 Traction roller material: Ethylene-Propylene-Diene Monomer

6.9 EPC Edge correction system

- Trimming device

7.1 Middle Section: 3 pcs

7.2 Edge Section device: 2 pcs

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for China Wholesale Pet Bottle Manufacturing Machine Factories – LQ5L-1800 Five-layer co-extrusion film blowing machine – UP Group, The product will supply to all over the world, such as: Florida, Slovak Republic, Slovenia, We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can offer the most competitive price with high quality,because we are much MORE PROFESSIONAL. You are welcomed to visit our company at any time.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

China Wholesale Pet Bottle Blowing Manufacturer...

-

China Wholesale Hand Operated Printing Device S...

-

China Wholesale Thermal Printing Machine Factor...

-

China Wholesale Print And Press Machine Factori...

-

China Wholesale Waste Paper Compactor Manufactu...

-

China Wholesale flexo printing press Factories ...