China Wholesale Plastic Container Moulding Machine Suppliers – Film Blown Machine – UP Group Detail:

Product Description

- MAIN TECHNICAL PARAMETERS

| Suitable Materials

Film Width Film Thickness Max.Output |

HDPE,LDPE,LLDPE,EVA

1000mm 0.02-0.2mm 150kg/hr |

HDPE,LDPE,LLDPE,EVA

1200mm 0.02-0.2mm 200kg/hr |

HDPE,LDPE,LLDPE,EVA

1500mm 0.02-0.2mm 260kg/hr |

HDPE,LDPE,LLDPE,EVA

2000mm 0.02-0.2mm 350kg/hr |

||||||

| EXTRUDER | Screw Diameter

L/D Screw Material Cylinder Material Cylinder Cooling Main Motor Temperature Control Average Power-consum. |

AФ50mm BФ60mm CФ50mm

30:1 SACM-645/38 CRMOALA SACM-645/38 CRMOALA 370w X 2/3 A18.5+B30+C18.5kw 3 X 3 60kw |

AФ55mm BФ60mm CФ55mm

30:1 SACM-645/38 CRMOALA SACM-645/38 CRMOALA 370w X 2/3 A22+B37+C22kw 3 X 3 80kw |

AФ60mm BФ65mm CФ60mm

30:1 SACM-645/38 CRMOALA SACM-645/38 CRMOALA 370w X 2/3 A30+B45+C30kw 4 X 3 100kw |

AФ65mm BФ75mm CФ65mm

30:1 SACM-645/38 CRMOALA SACM 645/38 CRMOALA 370w X 2/3 A37+B55+C37kw 4 X 3 120kw |

|||||

| DIE HEAD | Die size Air ring Air blower | Ф250mm

800mm

7.5kw |

Ф300mm

1000mm

11kw |

Ф400mm

1200mm

11kw |

Ф500mm

1600mm

18.5kw |

|

TAKE UP UNIT |

Roller width Take-up speed Take-up motor | Ф165 X 1200mm

5-70m/min 1.5kw |

Ф180 X 1400mm

5-60m/min 2.2kw |

Ф200 X 1700mm

5-50m/min 2.2kw |

Ф220 X 2200mm

5-40m/min 3kw |

| WINDING UNIT | Type

Winding motor Winding speed Dimension(LxWxH) |

Surface friction type 1.5kw

5-70m/min 7.0 X 4.5 X 7.5m |

Surface friction type 2.2kw

5-60m/min 8.5 X 5.5 X 8.5m |

Surface friction type 2.2kw

5-50m/min 9.0 X 6.0 X 10.5m |

Surface friction type 3kw

5-45m/min 10.0 X 6.5 X 12m |

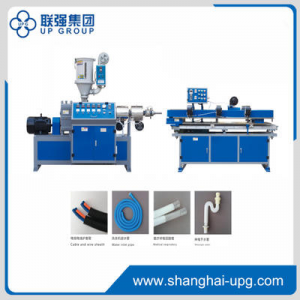

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for China Wholesale Plastic Container Moulding Machine Suppliers – Film Blown Machine – UP Group, The product will supply to all over the world, such as: Ukraine, Bulgaria, Seychelles, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.