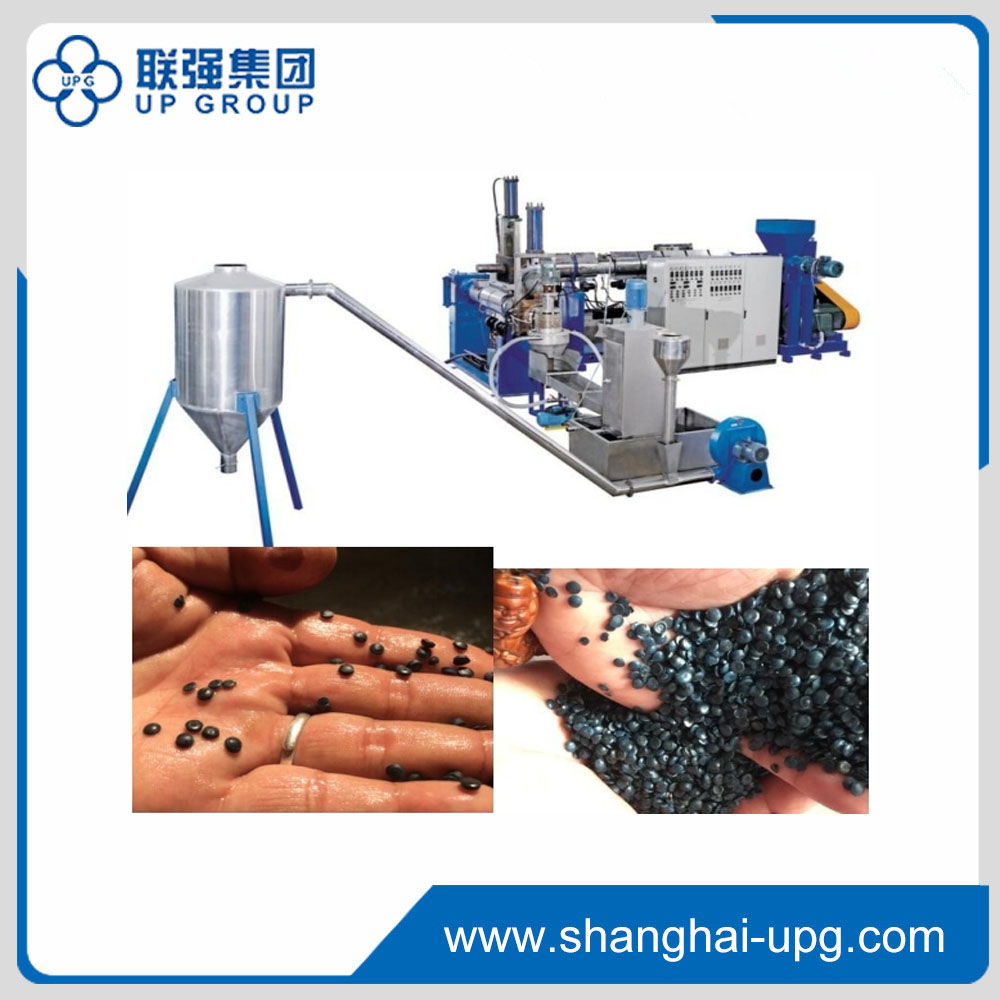

China Wholesale Plastic Pvc Cold Strand Granulation Line Factories – LQ150-200 PE Film Double-stage Pelletizing Line – UP Group Detail:

Detail Parameter

Detail parameter:

Belt conveyor

| Effective width | 600mm |

| Motor power | 1.5KW |

Agglomeration room

| Motor power | 45KW |

| Total Volume | 200L |

| Effective volume | 150L |

| Rotary blade | 9 |

| Fixed blade | 12 |

| Blades rotation speed | 900RPM |

LQ-SJ85/28 Extruder

| Driving motor | 55 KW, AC motor(SIMENS China) |

| Screw | |

| Diameter of screw | 85mm |

| L/D | 28/1 |

| Material of screw | 38CrMoAl |

| Surface treatment | Nitriding processing |

| Barrel | |

| Inner processing | nitride |

| Heating power | 55KW |

| Cooling air fans | 0.37KWx5 sets |

| Gear box | Special hard gear reducer |

| Venting system | |

| Vacuum pump | 2.2KWx1set |

| Electric cabinet | |

| Speed regulator | ABB inverter |

| Contactor | SIEMENS |

| Relay | Omron |

| Temperature controller | Omron |

Hydraulic screen changer

| Changing screen time≤2 sec | |

| Screen diameter | 200mm |

| Motor power | 1.5 KW |

LQ-SJ85/10 Extruder

| Driving motor | 22 KW, AC motor(SIMENS China) |

| Screw | |

| Diameter of screw | 85mm |

| L/D | 10/1 |

| Material of screw | 38CrMoAl |

| Surface treatment | Nitriding processing |

| Barrel | |

| Heating power | 22KW |

| Cooling air fans | 0.72KW |

| Gear box | Special hard gear reducer |

| Electric cabinet | |

| Speed regulator | ABB inverter |

| Contactor | SIEMENS |

| Relay | Omron |

| Temperature controller | Omron |

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

| Motor power | 1.1 KW |

| Water pump power | 3 KW |

| Blade | 2-4 pcs |

| Part contact with water is made of stainless steel (S.S.) | |

Conveying channel & water tank

Basic material of channel & tank body: stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

| Loading power | |

| Motor power | 3 KW |

| Conveying pipeline | S.S |

| Silo | |

| Material of storage silo | S.S |

| Silo frame | Carbon steel |

| Volume of silo | 500L |

Electric Controller

| Electronic control components(including circuit breakers, AC contactor, button, indicator light.) | |

| Temperature controller | OMRON |

| Contractor | SIEMENS |

| Other | DELIXI |

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our improvement strategy for China Wholesale Plastic Pvc Cold Strand Granulation Line Factories – LQ150-200 PE Film Double-stage Pelletizing Line – UP Group, The product will supply to all over the world, such as: Norway, Philippines, Marseille, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

-

China Wholesale Pet Bottle Injection Moulding M...

-

China Wholesale Hydraulic Plastic Baler Press M...

-

China Wholesale Paper Baler Machine Suppliers &...

-

China Wholesale Mini Plastic Injection Molding ...

-

China Wholesale Platen Die Cutting Machine Fact...

-

China Wholesale pvc lamination machine Supplier...