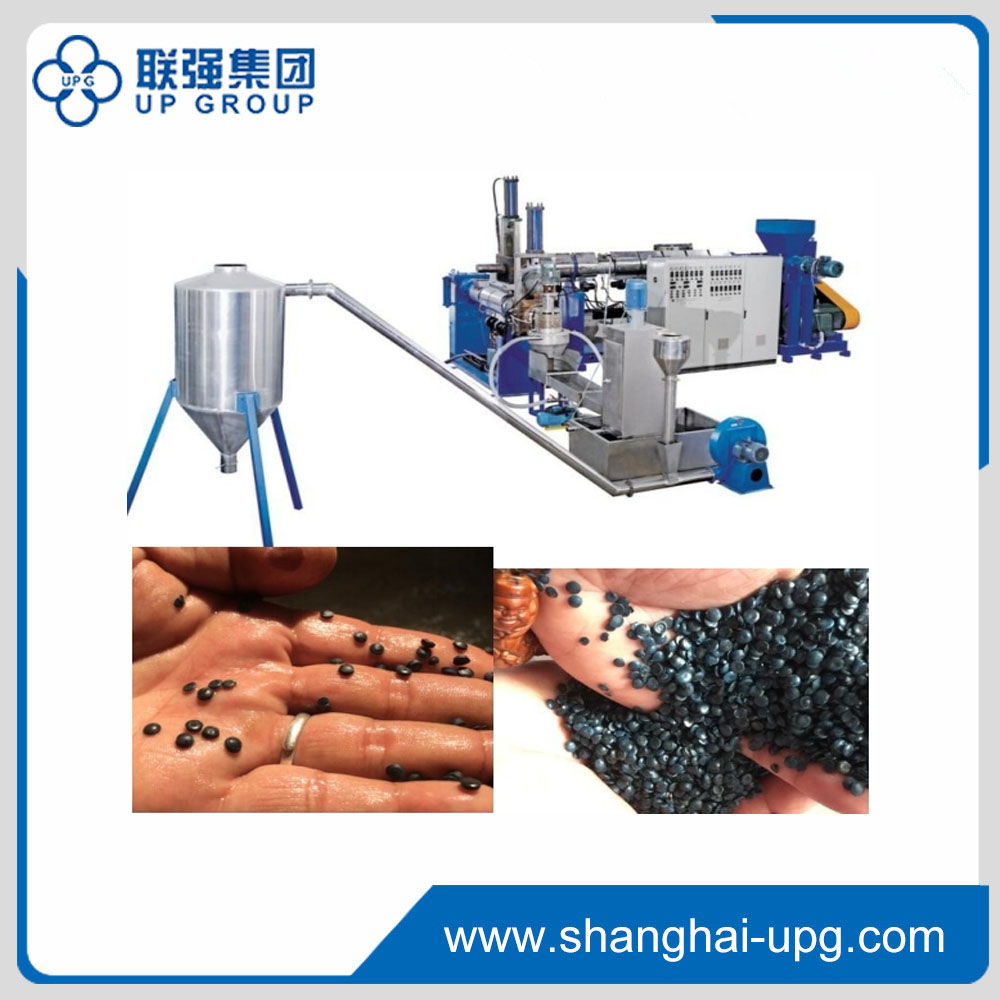

China Wholesale Plastic Recycling Granulation Manufacturers – LQ150-200 PE Film double-stage pelletizing line – UP Group Detail:

Detail parameter:

Belt conveyor

1.Effective width: 600mm

2.Motor power: 1.5KW

Agglomeration room

1.Motor power: 45KW 2.Total Volume: 200L

3.Effective volume:150L 4.Rotary blade: 9

5.Fixed blade: 12 6.Blades rotation speed: 900RPM

LQ-SJ85/28 Extruder

Driving motor:55 KW, AC motor(SIMENS China)

Screw:Diameter of screw: 85mm, L/D: 28/1

Material of screw: 38CrMoAl Surface treatment: Nitriding processing

Barrel:Inner processing: nitride

Heating power: 55KW Cooling air fans: 0.37KWx5 sets

Gear box: Special hard gear reducer

Venting system:Vacuum pump: 2.2KWx1set

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Changing screen time≤2 sec

Screen diameter: 200mm

Motor power: 1.5 KW

LQ-SJ85/10 Extruder

Driving motor: 22 KW, AC motor(SIMENS China)

Screw :

Diameter of screw: 85mm, L/D: 10/1

Material of screw: 38CrMoAl

Surface treatment: Nitriding processing

Barrel: Heating power: 22KW Cooling air fans: 0.72KW

Gear box: Special hard gear reducer

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

1.Motor power: 1.1 KW

2.Water pump power: 3 KW

3.Blade: 2-4 pcs

4.Part contact with water is made of stainless steel (S.S.)

Conveying channel & water tank

Basic material of channel & tank body:

stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

Loading power:

Motor power: 3 KW, conveying pipeline: S.S

Silo:

Material of storage silo: S.S; Silo frame: Carbon steel

Volume of silo: 500L

Electric Controller

Electronic control components(including

circuit breakers, AC contactor, button, indicator light.)

Temperature controller: OMRON

Contractor: SIEMENS

Other: DELIXI

Product detail pictures:

Related Product Guide:

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We're ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for China Wholesale Plastic Recycling Granulation Manufacturers – LQ150-200 PE Film double-stage pelletizing line – UP Group, The product will supply to all over the world, such as: Lithuania, Hungary, Australia, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.