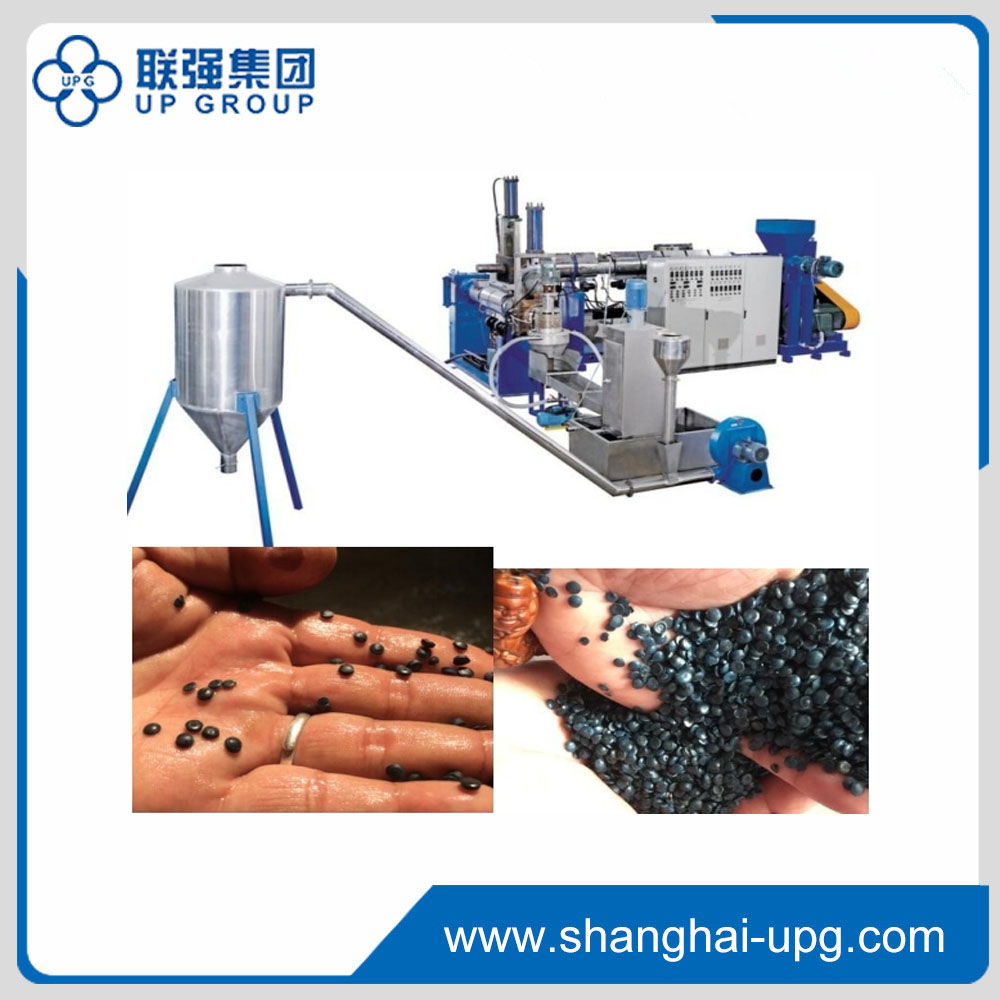

China Wholesale Recycled Granulation Suppliers – LQ150-200 PE Film double-stage pelletizing line – UP Group Detail:

Detail parameter:

Belt conveyor

1.Effective width: 600mm

2.Motor power: 1.5KW

Agglomeration room

1.Motor power: 45KW 2.Total Volume: 200L

3.Effective volume:150L 4.Rotary blade: 9

5.Fixed blade: 12 6.Blades rotation speed: 900RPM

LQ-SJ85/28 Extruder

Driving motor:55 KW, AC motor(SIMENS China)

Screw:Diameter of screw: 85mm, L/D: 28/1

Material of screw: 38CrMoAl Surface treatment: Nitriding processing

Barrel:Inner processing: nitride

Heating power: 55KW Cooling air fans: 0.37KWx5 sets

Gear box: Special hard gear reducer

Venting system:Vacuum pump: 2.2KWx1set

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Changing screen time≤2 sec

Screen diameter: 200mm

Motor power: 1.5 KW

LQ-SJ85/10 Extruder

Driving motor: 22 KW, AC motor(SIMENS China)

Screw :

Diameter of screw: 85mm, L/D: 10/1

Material of screw: 38CrMoAl

Surface treatment: Nitriding processing

Barrel: Heating power: 22KW Cooling air fans: 0.72KW

Gear box: Special hard gear reducer

Electric cabinet:

Speed regulator: ABB inverter

Contactor: SIEMENS Relay: Omron

Temperature controller: Omron

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

1.Motor power: 1.1 KW

2.Water pump power: 3 KW

3.Blade: 2-4 pcs

4.Part contact with water is made of stainless steel (S.S.)

Conveying channel & water tank

Basic material of channel & tank body:

stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

Loading power:

Motor power: 3 KW, conveying pipeline: S.S

Silo:

Material of storage silo: S.S; Silo frame: Carbon steel

Volume of silo: 500L

Electric Controller

Electronic control components(including

circuit breakers, AC contactor, button, indicator light.)

Temperature controller: OMRON

Contractor: SIEMENS

Other: DELIXI

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for China Wholesale Recycled Granulation Suppliers – LQ150-200 PE Film double-stage pelletizing line – UP Group, The product will supply to all over the world, such as: Ottawa, San Francisco, Estonia, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

-

China Wholesale Nail Cutting Machine Suppliers ...

-

China Wholesale Plastic Processing Machine Fact...

-

China Wholesale flexo plate making machine Fact...

-

China Wholesale Pvc Mixer Machine Factory ̵...

-

China Wholesale carry bag banane wali machine F...

-

China Wholesale Barrel Injection Molding Machin...