-

China Wholesale page laminator Factories – Medium Speed Dry Laminating Machine – UP Group

Product Description Medium Speed Dry Laminating Machine Laminating material Plastic film,Paper,Aluminium,etc. Laminating width 850.1050.1250mm Mechanical speed 180m/min Unwind web dia Φ600mm Rewind web dia Φ800mm -

pvc sheet making machine Factory – LQ-TM-54/76 Full Automatic Thermoforming Machine – UP Group

Features: Specification Suitable Material PET /PS /BOPS /HIPS /PVC/PLA Forming Area 540× 760mm Forming Depth 120mm Clamping Force 90 Ton Sheet Thickness Range 0.10-1.0 mm Max. Sheet Roll Diameter 710mm Max.Sheet Width 810mm Air Pressure 0.7 Mpa Water Consumption 6 Liters/min Air Consumption 1300 Liters/min Power Consumption 9kw/hr (Approximate) Production Speed 600-1200 recycles/hr Voltage Tri-phase, AC380V±15V, 50/... -

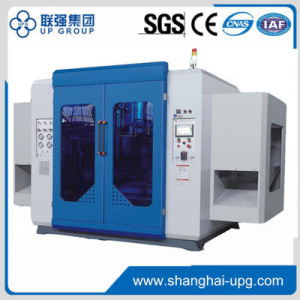

China Wholesale Pet Blow Moulding Machine Manufacturers – LQBC-80/90series blow molding machine (German model) – UP Group

Product Description 1.Linear guide support single frame,finite element analysis of the design, to ensure adequate clamping force, not up mode. 2.Large opening stroke,central locking,locking force equilibrium,no deformation. 3.High accuracy without the fusion line storage type die head,easy to change color,with servo wall thickness control system,improve product quality,reduce production costs. 4.optional with multi function under blowing mechanism,automatic machine to take the product o... -

China Wholesale First Printing Press Factories – BGF-1050 LAMINATION MACHINE – UP Group

Product Description Main Structure: (1) 1st unwind photoelectric EPC, air expanding shaft, 5kg magnetic powder detent, auto tension control (2) 2st unwinder air expanding shaft, 5kg magnetic powder detent, auto tension control (3) Rewind: air expanding shaft, 4KW ABB motor, Japanese YASKAWA (H1000) (4) Independent coating motor, inverter circuit synchronize control. Doctor blade glue cutting, inching: ±5mm, Doctor blade pressure: 10-100kg. (5) First second unwind and oven ... -

China Wholesale Ribbon Coding Machine Suppliers – LQAY800.1100 S/F/A/E/G Computerized Register Rotogravure Printing Machine – UP Group

Product Description LQAY800.1100 S 1. Chassisless connection structure. 2. The whole machine is equipped with 3 servo motor controlling system. 3.Tension is PLC control, touch screen operation is convenient and fast. 4. Vertical automatic register and video inspection system. 5. Double station unwinder and rewinder with automatic splicing. 6. Each printing unit is equipped with water cooling roller. 7. Electric heating, and gas heating, thermal oil heating and ESO heating dryer is option... -

China Wholesale Lamination Machine Factory – LQGF800.1100A Fully Automatic High-Speed Dry Laminating Machine – UP Group

Product Description 1. Independent external double station unwinder and rewinderwith automatic splicing function. 2. Unwind automatic tension control, equipped with EPC device. 3. 3 pace 9 meter oven, pneumatic open and close, each pace oven temperature independent control, equipped with exhaust system. 4. Ultrasonic EPC device is installed at the exit of oven. 5. Anilox roller gluing, inverter motor control. 6. Pneumatic doctor blade, pneumatic rubber roller. 7. Hot drum heating lamina... -

China Wholesale Solventless Laminating Machine Factories – ZHMG-401350(BS) Intelligent Rotogravure Printing Press for Decorative Paper – UP Group

Product Description Features: Coating synchronize with printing; Unwinding and rewinding with double working positions, controlled by PLC synchronously; With Japan’s Mitsubishi tension controller and automatic control Unwind tension; Optional dry method: Electricity heat、Steam、Thermal oil or Gas; Main components are famous brand. Parameter Max. Material Width 1350mm Max. Printing Width 1320mm Material Weight Range 30-190g/m² Max. Rewind/Unwind Diameter Ф1000mm Plate Cyl... -

China Wholesale vacuum thermoforming machine Manufacturers – LQ-TM-54/76 Full Automatic Thermoforming Machine – UP Group

Features: Specification Suitable Material PET /PS /BOPS /HIPS /PVC/PLA Forming Area 540× 760mm Forming Depth 120mm Clamping Force 90 Ton Sheet Thickness Range 0.10-1.0 mm Max. Sheet Roll Diameter 710mm Max.Sheet Width 810mm Air Pressure 0.7 Mpa Water Consumption 6 Liters/min Air Consumption 1300 Liters/min Power Consumption 9kw/hr (Approximate) Production Speed 600-1200 recycles/hr Voltage Tri-phase, AC380V±15V, 50/... -

China Wholesale Bottle Molding Machine Manufacturers – LQBUD-80&90 blow molding machine – UP Group

Product Description 1. This blow molding machine is suitable for the production of 200ml-10L plastic hollow products,the use of curved elbow lock system,low energy consumption,the center of the lock,the lock force,speed faster,run more smoothly. 2. Die opening and closing system:specially designed for Heng lock mould mechanism using a high pressure mode locking,locking plate stress in the centre of the template,clamping force,open the rigid lock template,even if the ultra wide die is al... -

China Wholesale Hydraulic Press Factory – PET/PVC Shrink Sleeve Glue Sealing Machine – UP Group

Product Description Features Web guiding system provides an accurate sleeve seaming position. Equipped with blower for drying the glue faster and also increasing the production speed. Stroboscope light to check printing quality is available through instant vision conservation. Entire machine is controlled by PLC,HMI touch screen operation. Unwind adopts Taiwan magnetic powder brake, tension is automatic; The remaining material will stop automatically. Nip rollers are driven by one servo motor... -

China Wholesale Head Cutting Machine Factory – LQ-1250 High Speed Dry Laminating Machine – UP Group

Product Description LQ-1250 High Speed Dry Laminating Machine Laminating material Plastic film,Paper,Aluminium,etc. Laminating width 850.1050.1250mm Mechanical speed 250m/min Tension systerm Ten-motor(glue press roller motor) Unwind web dia Φ600mm Rewind web dia Φ800mm -

China Wholesale Plastic Compression Machine Suppliers – LQBC-80/90series blow molding machine (German model) – UP Group

Product Description 1.Linear guide support single frame,finite element analysis of the design, to ensure adequate clamping force, not up mode. 2.Large opening stroke,central locking,locking force equilibrium,no deformation. 3.High accuracy without the fusion line storage type die head,easy to change color,with servo wall thickness control system,improve product quality,reduce production costs. 4.optional with multi function under blowing mechanism,automatic machine to take the product o...