home vacuum forming machine Manufacturers – LQ-TM-51/62 Full Automatic Thermoforming Machine – UP Group Detail:

Specifications

Suitable Material: PET /PS /BOPS /HIPS /PVC/PLA

Forming Area: 510×620mm

Forming Depth: 100mm

Sheet Thickness Range: 0.10-1.0 mm

Clamping Force: 55 Ton

Max. Sheet Roll Diameter: 710mm

Max.Sheet Width: 680mm

Air Pressure: 0.7 Mpa

Water Consumption: 5 Liters/min

Air Consumption: 1000 Liters/min

Production Speed: 600-1200 cycles/hr

Voltage: AC380V±15V,50/60HZ (Tri-Phase)

Total Motor Power: 8 kw

Total Heating Power: 24 kw

Knife Length: APET:6000mm / PVC PLA:7000mm / OPS:10000mm

Weight: 3500kg

Machine Dimensions(mm): Machine:2950(L)×1550(W)×2350(H)

Stacker: 2670(L)*670(W)*2350(H)

BRIEF INTRODUCTION

This flly automatic plastic thermoforming machine is a combination of mechanical, electrical and pneumatic components, and the whole system is contrlled by a micro PLC, which can be operated in man-interface.

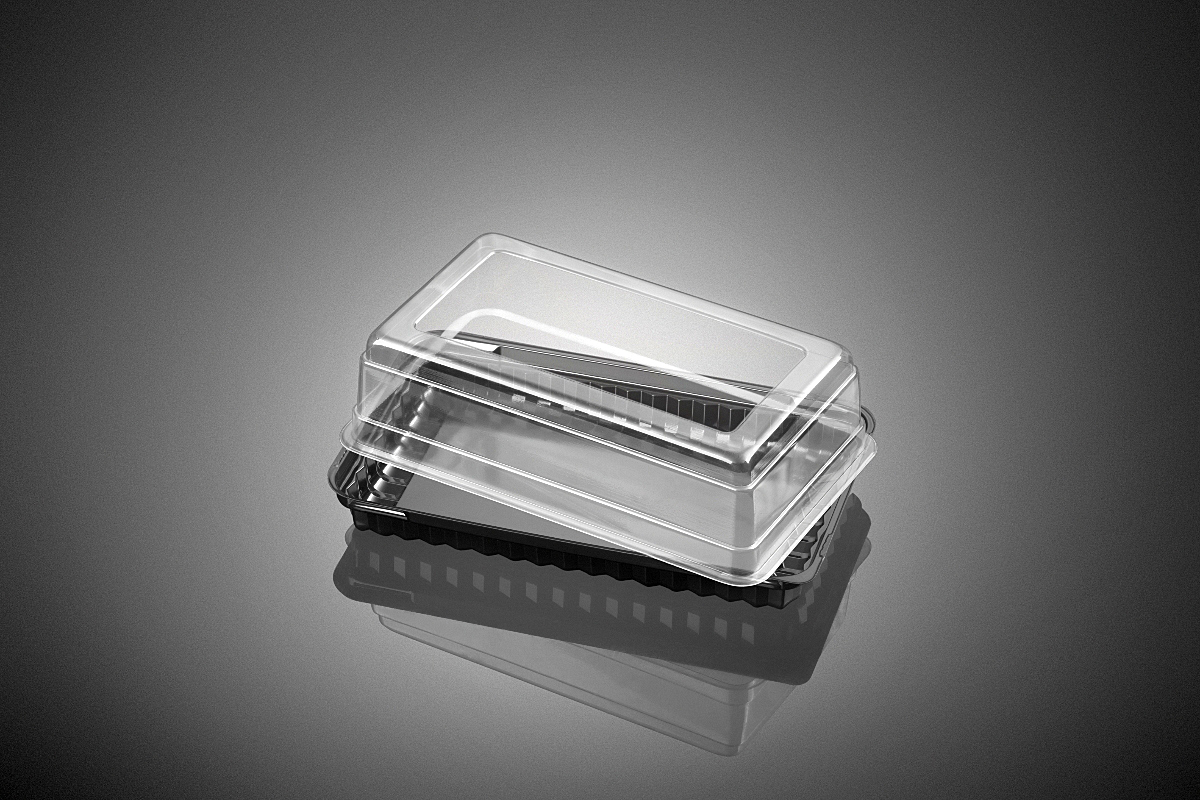

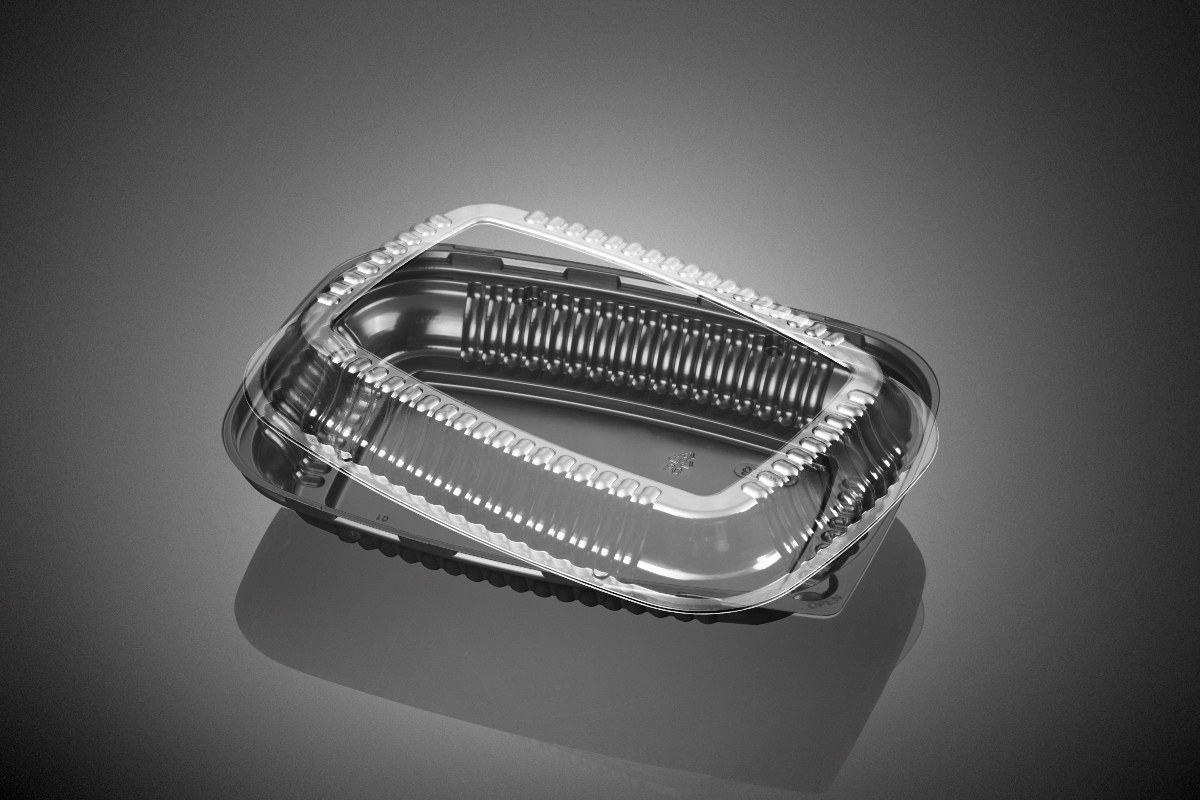

It combines the material feeding, heating, forming, cutting and stacking into one process. It’s available for BOPS, PS, APET, PVC, PLA plastic sheet roll forming into various of lids, dishes, trays,

clamshells and other products, such as lunch box lids, sushi lids, paper bowl lids, aluminum foil lids, moon cake trays,pastry trays, food trays, supermarket trays, oral liquid trays,medicine injection trays.

|

Suitable Material |

PET /PS /BOPS /HIPS /PVC/PLA |

|

Forming Area |

510×620mm |

|

Forming Depth |

100mm |

|

Sheet Thickness Range |

0.10-1.0 mm |

|

Clamping Force |

55 Ton |

|

Max. Sheet Roll Diameter |

710mm |

|

Max.Sheet Width |

680mm |

|

Air Pressure |

0.7 Mpa |

|

Water Consumption |

5 Liters/min |

|

Air Consumption |

1000 Liters/min |

|

Production Speed |

600-1200 cycles/hr |

|

Voltage |

AC380V±15V,50/60HZ (Tri-Phase) |

|

Total Motor Power |

8 kw |

|

Total Heating Power |

24 kw |

|

Knife Length |

APET:6000mm / PVC PLA:7000mm / OPS:10000mm |

|

Weight |

3500kg |

|

Machine Dimensions(mm) |

Machine:2950(L)×1550(W)×2350(H) Stacker:2670(L)*670(W)*2350(H) |

Termsof Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping.Or irrevocable L/C at sight

Installation and Training

The price includes the fee of installation, Training and interpreter, However,the relative cost such as international return air tickets between China and Buyer’s country, local transportation, accommodation (3 star hotel), and the pocket money per person for engineers and interpreter will be born by buyer. Or, the customer can find capable interpreter in local. If during Covid19, will do online or video support by whatsapp or wechat software.

Warranty:12 months after B/L date

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency.

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for home vacuum forming machine Manufacturers – LQ-TM-51/62 Full Automatic Thermoforming Machine – UP Group, The product will supply to all over the world, such as: Algeria, Kuwait, Jamaica, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.