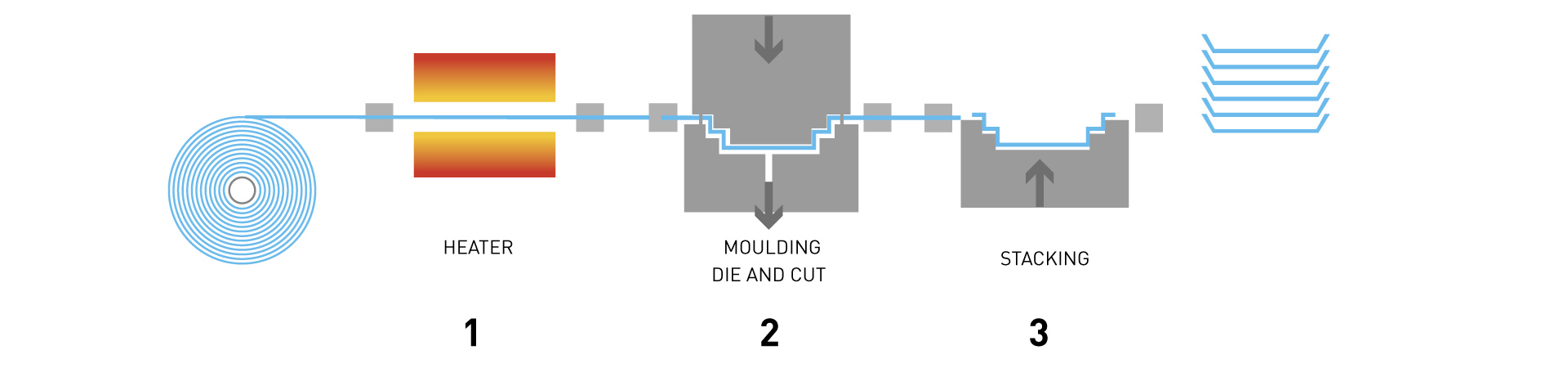

Production Process

Main Features

● Suitable for PP, APET, PVC, PLA, BOPS, PS plastic sheet.

● Feeding, forming, cutting, stacking are driven by servo motor.

● Feeding, forming, in-mould cutting and stacking processing are complete production automatically.

● Mould with rapid change device, easy maintenance.

● Forming with 7bar air pressure and vacuum.

● Double selectable stacking systems.

Specification

| Model | LQ-TM-3021 | |

| Max Forming Area | 760*540mm | |

| Max Forming Depth/Height | Manipulator: 100mm Downward stacking: 120mm |

|

| Sheet Thickness Range | 0.2-1.5mm | |

| Production Speed | 600-1500 cycles/hr | |

| Clamping force | 100Ton | |

| Heating Power | 114 KW | |

| Motor Power | 33 KW | |

| Air Pressure | 0.7Mpa | |

| Air Consumption | 3000 liter/min | |

| Water Consumption | 70 liter/min | |

| Power Supply | Tri-phase, AC 380±15V, 50HZ | |

| Sheet Roll Dia. | 1000mm | |

| Weight | 10000 Kg | |

| Dimension (mm) |

Main Machine | 7550*2122*2410 |

| Feeder | 1500*1420*1450 | |

Machine Introduction

Forming & CuttingStation

● Panasonic PLC easy operation.

● Forming Column: 4 PCS.

● Stretching by servo motor Yaskawa Japan.

● Sheet feeding by servo motor Yaskawa Japan.

Heating Oven

● (Upper/ Lower Ceramic infrared).

● PID type temperate control.

● The heater temperature for each unit and zone adjusted on Screen.

● Automatic out when machine accident stop.

Forming Mould

● Rapid mould changing device.

● Mould automatic memory system.

● High accuracy and high yield products.

● Both positive or negative forming.

● Fast mould changing system. ---------- As reference

Cutting Mould

● Ruler cutter for wider range of product.

● Ruler cutter is from Japan.

Stacking Station

● Inmould and downward can be chosen according to product type.

● Stacking setted number of product in a stack Automatically.

● PLC Control.

● Robot arm driven by servo motor Yaskawa Japan.

● Automatically stacking and counting for more sanitary and save labor.