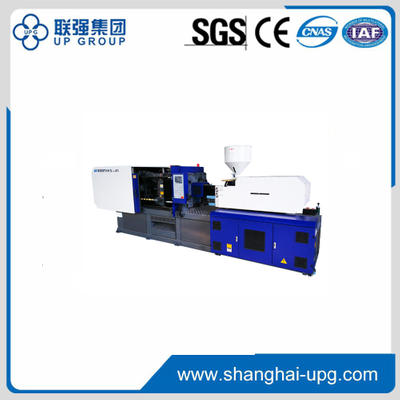

Product Description

● The system pressure and flow of the servo injection molding machine are double closed-loop, and the hydraulic system supplies oil according to the actual flow and pressure, which overcomes the high energy consumption caused by the high pressure overflow of the common quantitative pump system. The motor works according to the set speed in the high flow stage such as pre molding, mold closing and glue injection, and reduces the motor speed in the low flow stage such as pressure maintaining and cooling. The oil pump motor actually can Consumption has been reduced by 35% - 75%.

● The advantages of servo injection molding machine, such as energy saving, environmental protection, high repetition accuracy, reliability and durability, have been favored by the market and praised by users.

Specification

| Model |

HHF68X-J5 | HHF110X-J5 | HHF130X-J5 | HHF170X-J5 | HHF230X-J5 | ||||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

| INJECTION UNIT | |||||||||||||||

| Screw Diameter | 28 (mm) | 30 (mm) | 32 (mm) | 35 (mm) | 38 (mm) | 42 (mm) | 38 (mm) | 42 (mm) | 45 (mm) | 40 (mm) | 45 (mm) | 48 (mm) | 45 (mm) | 50 (mm) | 55 (mm) |

| Screw L/D Ratio | 24.6 (L/d) | 23 (L/d) | 21.6 (L/d) | 24.6 (L/d) | 24.3 (L/d) | 22 (L/d) | 24.3 (L/d) | 22 (L/d) | 20.5 (L/d) | 24.8 (L/d) | 22 (L/d) | 20.6 (L/d) | 26.6 (L/d) | 23.96 (L/d) | 21.8 (L/d) |

| Shot size | 86 (cm3) | 99 (cm3) | 113 (cm3) | 168 (cm3) | 198 (cm3) | 241 (cm3) | 215 (cm3) | 263 (cm3) | 302 (cm3) | 284 (cm3) | 360 (cm3) | 410 (cm3) | 397 (cm3) | 490 (cm3) | 593 (cm3) |

| Injection Weight (PS) | 78 (g) | 56 (g) | 103 (g) | 153 (g) | 180 (g) | 219 (g) | 196 (g) | 239 (g) | 275 (g) | 258 (g) | 328 (g) | 373 (g) | 361 (g) | 446 (g) | 540 (g) |

| Injection Rate | 49 (g/s) | 56 (g/s) | 63 (g/s) | 95 (g/s) | 122 (g/s) | 136 (g/s) | 122 (g/s) | 150 (g/s) | 172 (g/s) | 96 (g/s) | 122 (g/s) | 138 (g/s) | 103 (g/s) | 128 (g/s) | 155 (g/s) |

| Plasticizing Capacity | 6.3 (g/s) | 8.4 (g/s) | 10.3 (g/s) | 11 (g/s) | 12 (g/s) | 15 (g/s) | 11 (g/s) | 14 (g/s) | 17 (g/s) | 16.2 (g/s) | 20 (g/s) | 21 (g/s) | 19 (g/s) | 24 (g/s) | 29 (g/s) |

| Injection Pressure | 219 (Mpa) | 191 (Mpa) | 168 (Mpa) | 219 (Mpa) | 186 (Mpa) | 152 (Mpa) | 176 (Mpa) | 145 (Mpa) | 126 (Mpa) | 225 (Mpa) | 178 (Mpa) | 156 (Mpa) | 210 (Mpa) | 170 (Mpa) | 140 (Mpa) |

| Screw Speed | 0-220 (rpm) | 0-220 (rpm) | 0-220 (rpm) | 0-185 (rpm) | 0-185 (rpm) | ||||||||||

| CLAMPING UNIT | |||||||||||||||

| Clamp Tonnage | 680 (KN) | 1100 (KN) | 1300 (KN) | 1700 (KN) | 2300 (KN) | ||||||||||

| Toggle Stroke | 300 (mm) | 320 (mm) | 360 (mm) | 430 (mm) | 490 (mm) | ||||||||||

| Space Bet. Tie-bars | 310x310 (mm) | 370x370 (mm) | 430x415(415x415) (mm) | 480x480(470x470) (mm) | 532x532 (mm) | ||||||||||

| Max.Mold height | 330 (mm) | 380 (mm) | 440 (mm) | 510 (mm) | 550 (mm) | ||||||||||

| Min.Mold height | 120 (mm) | 140 (mm) | 140 (mm) | 170 (mm) | 200 (mm) | ||||||||||

| Ejector Stroke | 80 (mm) | 100 (mm) | 120 (mm) | 140 (mm) | 140 (mm) | ||||||||||

| Ejector Tonnage | 38 (Kn) | 45 (Kn) | 45 (Kn) | 45 (Kn) | 70 (Kn) | ||||||||||

| Ejector Number | 5 (PC) | 5 (PC) | 5 (PC) | 5 (PC) | 9 (PC) | ||||||||||

| OTHERS | |||||||||||||||

| Max.Pump Pressure | 16 (Mpa) | 16 (Mpa) | 16 (Mpa) | 16 (Mpa) | 16 (Mpa) | ||||||||||

| Pump Motor Power | 7.5 (Kw) | 11 (Kw) | 13 (Kw) | 15 (Kw) | 18.5 (Kw) | ||||||||||

| Heater Power | 6.15 (Kw) | 9.8 (Kw) | 9.8 (Kw) | 11 (Kw) | 16.9 (Kw) | ||||||||||

| Machine Dimension | 3.4x1.1x1.5 (m) | 4.2x1.15x1.83 (m) | 4.5x1.25x1.86 (m) | 5.1x1.35x2.1 (m) | 5.5x1.42x2.16 (m) | ||||||||||

| Machine Weight | 2.6 (T) | 3.4 (T) | 3.7 (T) | 5.2 (T) | 7 (T) | ||||||||||

| Oil Tank Cap | 140 (L) | 180 (L) | 210 (L) | 240 (L) | 340 (L) | ||||||||||

-

LQ PVC Single/Multi Layer Heat Insulation Corru...

-

LQGZ Series Intermediate Speed Corrugated Pipe ...

-

LQYJH82PC-25L Fully Automatic 25L Blow Molding ...

-

LQ AS Injection-stretch-blow molding machine wh...

-

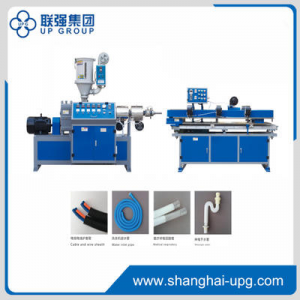

LQ XRXC Series Plastic Profile Extrusion Line W...

-

LQX 55/65/75/80 Blow Molding Machine Manufacturer