Product Description

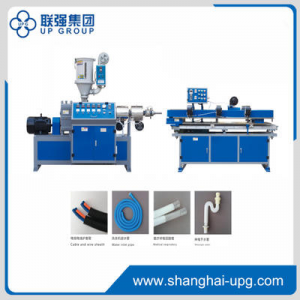

1. Extruder

● Screw diameter: 65; 55; 65; 55;65

● L/D ratio: 30:1

● Max screw speed:100r/min

● Screw Structure: Mixed type, with barrier

● Screw and Barrier material: 38CrMoAl, Bi-metallic

● Heater type: ceramic heater.

● Temperature Control: 5 zone; 4zone; 5 zone; 4 zones;5 zones

● Barrel Heater power: 60kw

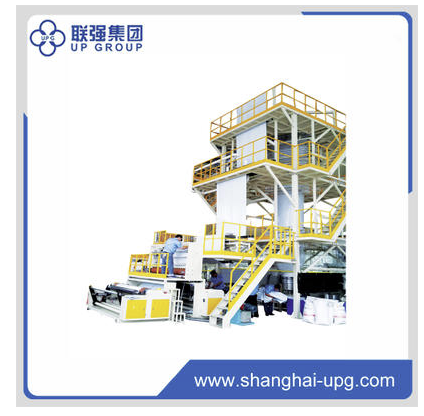

● Main motor: 37KW; 30kw; 37kw; 30kw; 37KW. (SIEMENS BEIDE)

● Inverter: 37KW; 30kw; 37kw; 30kw; 37KW. (SINEE)

● Gear box size: A: 200#, B: 180#, C: 200#, D: 180#, E: 200# (SHANDONG WUKUN)

● Screen Changer: hydraulic screen changer: 5 sets

2. Die head

● Die head type: A+B+C+D+E fixed IBC type die head.

● Die head material: Alloy steel forging and heat treatment;

● Die head width: ◎400mm

● Channel and surface hard chromium plating

● Heater: Aluminum ceramics heater.

3. Cooling Device (with IBC system)

● Type: 800mm double lips air ring

● Material: cast aluminum.

● Main Air blower: 11 kw:

● Film bubble cold air exchange device; Hot air channel and cold air channel mutual independence.

● Film Bubble monitor sensor: Import ultrasound Probe (3 sets), Controlling the film bubble size.

● Inlet air blower: 7.5kw

● Outlet air blower: 7.5kw

● Automatic wind, automatic air suction

4. Bubble Stabilizing frame

● Structure: Circular type

5. Collapsing Frame & Gusset board

● Material: Steel structure frame with special material

● Adjusting mode:manual

6. Haul-off Ocillation Traction System

● Traction roller: 1800mm

● Effective film width: 1600mm

● Traction Motor power: 4.5kw (adjust by inverter) three-phase asynchronous motor

● Traction speed: 70m/min

● Up traction rotating motor: 4.5kw (adjust by inverter)

● Down traction motor: 4.5kw (adjust by inverter)

● Moving of the roll is driven by pneumatic

● Traction roller material: Ethylene-Propylene-Diene Monomer

● EPC Edge correction system

7. Trimming device

● Middle Section: 3 pcs

● Edge Section device: 2 pcs

8. Manual Back to Back Double Winders

|

No. |

Parts |

Parameters |

Quantity |

Brand |

| 1 |

Winding Motor |

4.5 kw |

2 sets |

|

| 2 |

Winding Inverter |

4.5 kw |

2 sets |

Sinee Inverter |

| 3 |

traction Motor |

4.5 kw |

1 set\ |

|

| 4 |

traction Inverter |

4.5 kw |

1 set |

Sinee Inverter |

| 5 |

Main winding rubber roller |

EPDM |

2 pcs |

EPDM |

| 6 |

Banana roller |

Encapsulated |

2 pcs |

|

| 7 |

PLC |

1 set |

Delta |

|

| 8 |

Air shaft |

Diameter Φ76mm |

4 pcs |

|

| 9 |

Air cylinder |

Airtac Taiwan | ||

| 10 |

Flying Knife |

2.0M |

2 pcs |

9. Regular electrical control system (CE certificate)

|

No |

Item |

Brand |

|

1 |

Electric appliance: Switch, button, contractor etc. |

Delixi Electric |

|

2 |

Main Motor Inverter |

SINEE |

|

3 |

Solid state relay |

FORTEK TAIWAN |

|

4 |

Machine cable |

International standards |

|

5 |

Temperature controller |

HUIBANG |

10. Tower

● Structure: Disassemble, with safety operating platform and protective barrier

Specification

| Film Thickness (MM) | 0.02-0.2 |

| Film Width (MM) | 1600 |

| Film thickness tolerance | +-6% |

| Suitable Material | PE; Tie; PA |

| Extrusion Output (KG/H) | 200-300 |

| Total Power (KW) | 280 |

| Voltage (V/HZ) | 380/50 |

| Weight (KG) | About 15000 |

| Over Dimension: (L*W*H) MM | 10000*7500*11000 |

| Certification: CE;SGS BV | |