In recent years, advances in recycling machinery have revolutionised the recycling industry's processes, making them more efficient, economical and environmentally friendly. The recycling industry process plays a vital role in reducing waste and conserving natural resources and involves the collection, sorting, processing and manufacture of waste materials into new products. This process not only helps to minimise the impact of waste on the environment but also contributes to the sustainable use of resources.

Recycling machinery includes a wide range of equipment and technologies designed to automate and rationalise all stages of the recycling process, from material sorting and shredding to baling box granulation, which greatly improves the overall efficiency and productivity of recycling operations. Let's take an in-depth look at the key aspects of the recycling industry process and explore how recycling machinery is transforming sustainable waste management.

The first step in the industrial recycling process is the collection and sorting of recyclable materials. Traditionally, this has required manual labour and basic sorting equipment, however, with the advent of advanced recycling machinery, the process has become much more complex and precise. Automated sorting systems equipped with sensors, conveyor belts and optical scanners can identify and separate different types of materials such as plastics, glass, paper and metals with high accuracy. This not only reduces the reliance on manual labour, but also ensures the high purity of recyclable materials, making them more valuable on the market.

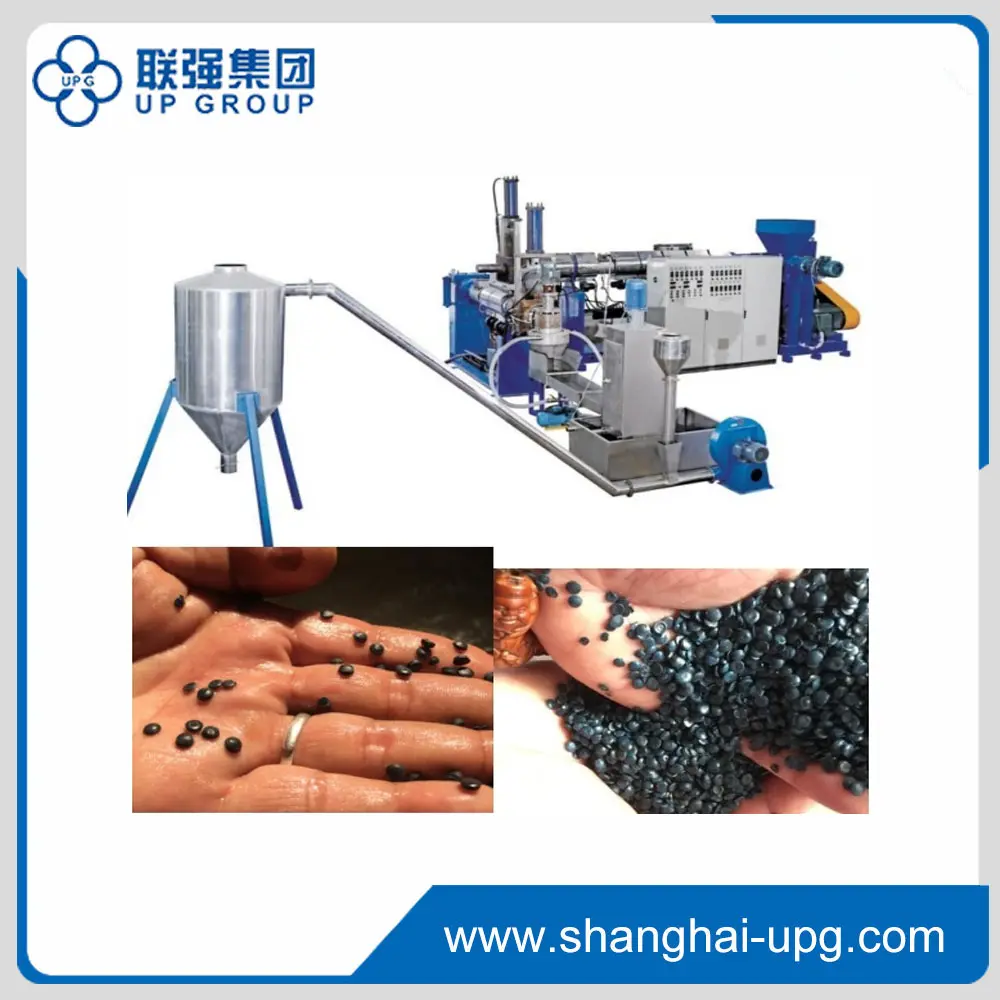

Allow us to introduce you to one of the recycling machines manufactured by our company. LQ-150/200 china fully automatic PE film plastic recycling machine manufacturers

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency.

Once materials are sorted, they are shredded and crushed to break them down into smaller pieces and particles, and this is where recycling machinery, such as industrial shredders and granulators, play a key role. These machines are able to process a wide range of materials, such as plastics, rubber, wood, and metal, into uniform granules or flakes, and the crushed material is easier to handle, transport, and further process, which is more conducive to recycling and remanufacturing.

In plastics and glass recycling, cleaning and drying are important steps in removing contaminants and impurities from the waste material. Recycling machinery such as washing lines and drying systems are designed to effectively wash and dry materials to ensure they meet the quality standards required for recycling. Not only do these machines improve the overall cleanliness of recovered materials, they also promote water conservation and environmental sustainability through water recycling and filtration capabilities.

Baling and compaction equipment is used to compress and package processed materials into dense, easy-to-handle bales or compacted forms. For example, balers are commonly used to compact materials such as cardboard, paper, plastics and metals into tight bales that can be easily stored, transported and sold to recycling facilities. Similarly, compactors are used to reduce the volume of materials such as foams, plastics and textiles, optimising storage space and improving transport efficiency.

For some materials, such as plastics, pelletising and extrusion processes are used to convert chopped or pelletised plastics into uniform pellets or extruded products. Recycling machinery such as pelletisers and extruders use heat and pressure to melt and remould plastic pellets into new shapes that can be used in the manufacture of a wide range of plastic products. This closed-loop approach to plastics recycling not only reduces reliance on virgin plastics, but also minimises the environmental impact of plastic waste.

Overall, the integration of recycling machinery into the recycling industry process can significantly improve the efficiency, quality and sustainability of waste management practices. These cash technologies not only streamline the recycling process, but also open up new opportunities for companies to innovate and create value from recycled materials. As the demand for sustainable waste management solutions continues to grow, the role of recycling machinery in driving the recycling industry forward cannot be underestimated. It is clear that the continued development and adoption of recycling machinery will play a key role in shaping the future of recycling and resource conservation globally. Everyone is welcome to contact our company in a timely manner if you have any need for recycling machinery or any specialised questions for advice, we will wholeheartedly provide you with quality products and services.

Post time: Aug-26-2024