Pelletising, a key process in the production of plastic products, focuses on the recycling and production of plastic pellets, which are the raw material for a variety of applications such as film production, injection moulding and extrusion. There are a number of pelletising technologies available, among which the film bi-stage pelletising production line stands out as being more equipped with the efficiency and effectiveness to produce high-quality pellets from plastic waste materials.

Converting raw materials such as waste plastics into small, uniform pellets is the process of pelletising, and the entire process of pelletising includes, feeding, melting, extruding, cooling and cutting to create pellets that can be easily handled, transported and processed in subsequent stages of production.

Pelletising technologies can be broadly divided into two categories: single-stage pelletising and two-stage pelletising. Single-stage pelletising uses one extruder to melt the material and make the pellets, whereas two-stage pelletising uses two extruders, allowing for more precise control of the melting and cooling process, resulting in higher quality pellets.

The film two-stage pelletising line is designed for processing plastic films such as polyethylene (PE) and polypropylene (PP). The technology is particularly suitable for recycling post-consumer plastic films, which are often difficult to process due to their low density and tendency to stick together.

Feeding and pre-processing involves first feeding the system with plastic film scrap, which is often torn into small pieces to facilitate handling and processing. Pre-treatment may also include drying the material to remove moisture, which is essential for optimum melting and pelletising.

In the first stage, the shredded plastic film is fed into the first extruder, which is equipped with a screw that melts the material by mechanical shearing and heating. The melted plastic is then forced through a screen to remove impurities and ensure uniform melting.

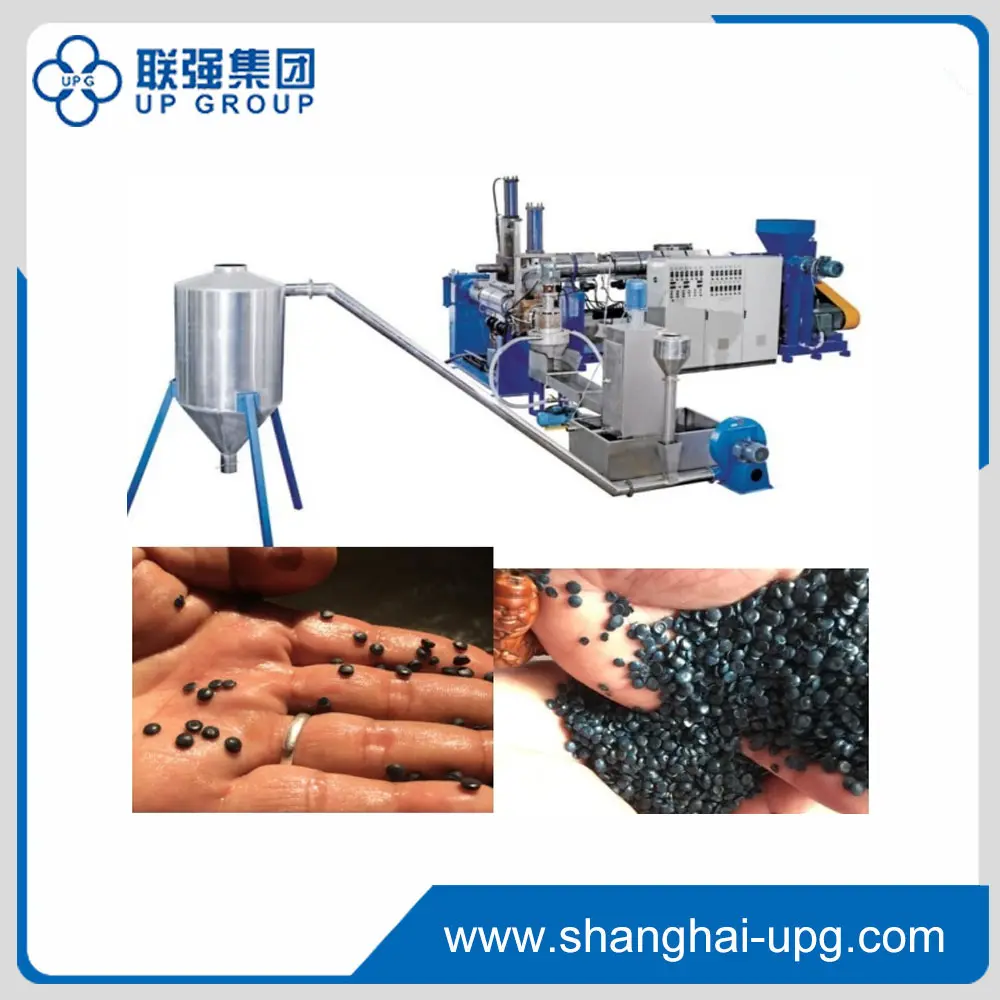

Insert, please consider our company’s this product, LQ250-300PE Film Double-Stage Pelletizing Line

From the first extruder, the molten material passes into the second extruder, a stage that allows for further homogenisation and degassing, which is essential to remove any residual volatiles or moisture that may affect the quality of the final pellet. The second extruder is usually run at a lower speed, which helps to maintain the properties of the plastic.

After the second stage of extrusion, a pelletiser is used to cut the molten plastic into pellets, which can be cooled either underwater or by air, depending on the specific requirements of the production process. The pellets produced are uniform in size and shape and are suitable for a variety of applications.

Once the pellets are moulded, they need to be cooled and solidified, and then dried to remove excess moisture. Proper cooling and drying is critical to ensure that the pellets maintain their integrity and do not clump.

Finally, the pellets are packaged for storage or transport, a process designed to minimise contamination and ensure that the pellets are in optimum condition before use.

Below are some examples of the advantages of a dual-stage pelletising line for films:

- Higher pellet quality: the two-stage process allows better control of the melting and cooling process, resulting in higher quality pellets with improved physical properties.

- Higher contaminant removal: The two-stage extrusion process effectively removes contaminants and volatiles, resulting in cleaner, more consistent pellets.

- Versatility: The technology can process a wide range of plastic films, making it suitable for a variety of recycling applications.

- Energy efficiency: Bipolar systems are typically designed to consume less energy than single-stage systems, making them a more sustainable option.

- Reduced downtime: the efficient design of the film bi-stage pelletising line minimises downtime during production, resulting in increased output and productivity.

Pelletising technology plays a vital role in the recycling and production of plastic products. Film two-stage pelletising lines represent a major advancement in this field, improving efficiency, quality and versatility. As the demand for sustainable plastics solutions continues to grow, the importance of effective pelletising technology will increase daily. By investing in advanced systems such as film two-stage pelletising lines, manufacturers can contribute to a more sustainable future while meeting the needs of their customers, so if you are interested in film two-stage pelletising lines, please do not hesitate to contact our company.

Post time: Dec-30-2024