Features

Web guiding system provides an accurate sleeve seaming position.

Equipped with blower for drying the glue faster and also increasing the production speed.

Stroboscope light to check printing quality is available through instant vision conservation.

Entire machine is controlled by PLC,HMI touch screen operation.

Unwind adopts Taiwan magnetic powder brake, tension is automatic; The remaining material will stop automatically.

Nip rollers are driven by one servo motor, Achieve constant linear velocity control and effectively cut off rewind and unwind tensions’ intervened.

Rewinds adopt servo motors, tension is automatic controlled by PLC.

Equipped with tension load cell assure extremely stable rewinding tension without the need to adjust it when speed and diameter varied.

Optional device

Rewind oscillation device.

The ultrasonic with measuring device.

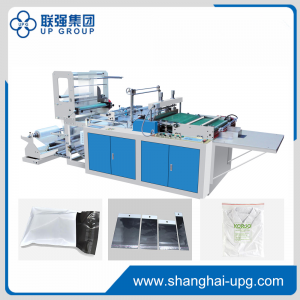

Applications

Designed for the center seaming operation of shrink sleeves such as PVC,OPS,PET...

Main Technical Specification

Max Sealing width Min Sealing width Unwind diameter Rewind diameter Mechanical speed Tolerance of EPC power Power supply Weight

一、 Main technical specifications

- (Applications) :PVC,PETG,OPS

- thickness 30-100μ

- (Unwind diameter): Ø500mm(Max);

- (Unwind inner diameter): 3"/76mm;

- (Material width): ≤820mm;

- (Mechanical speed): 0- 600m/min;

- (Tube width): 30-350mm

- (Rewind diameter): Ø700mm(Max);

- (Rewind inner diameter): 3"/76mm;

- (Total power): ≈9Kw;

- (Voltage): AC 380V50Hz (三相四线制);

- (Overall dimension): L3100mm*W1650mm*H1600mm;