pinch bottom bag making machine Manufacturers – LQD-600C Three-side Sealing Automatic Bag Making Machine – UP Group

Product Detail

Product Tags

Related Video

Feedback (2)

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for Hand Press Molding Machine, Plastic Pet Bottle Machine, Plastic Crate Injection Molding Machine, We cordially welcome shoppers from in the home and overseas to hitch us and cooperate with us to enjoy a better future.

pinch bottom bag making machine Manufacturers – LQD-600C Three-side Sealing Automatic Bag Making Machine – UP Group Detail:

Specification

| Mode |

three side sealing, seven servos, four feeding, main machine servo, moveable double cut. With ultrasonic device. |

| Raw material |

BOPP, CPP, PET, NYLON, plastic laminated film, multiplayer extrusion blown film, pure aluminum, aluminum-plating laminated film, paper-plastic laminated film |

| Max. bag making speed |

180 time/min |

| Normal speed |

120time/min (three side seal 100-200mm) |

| 4Max. material out feeding line speed |

≤35 m/min |

| Size of bag

|

| Width |

80-580 mm |

| Length |

80-500 mm (dual delivery function) |

| Width of sealing |

6-60 mm |

| Bag style |

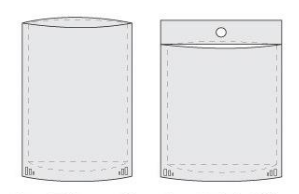

three-side sealing bag, Standing bag, Zip bag and four side sealing |

| Size of material roll |

Ø 600*1250 mm |

| Positioning accuracy |

≤±1 mm |

| Thermal sealing knife quantity |

Four teams on vertical thermal sealing, four teams on vertical cooling setup. Two teams on zipper thermal sealing knifes, two teams cooling units. Three teams on horizontal thermal sealing, two teams on horizontal cooling setup |

| Temperature control quantity |

22 routes |

| Temperature control setting range |

normal and up to 360℃ |

| Power of whole machine |

45KW |

| Overall dimension (length*width*height) |

14100*1750*1900 |

| Net weight of whole machine |

about 6500Kg |

| Color |

main machine body is black, cover is milk white. |

| Noise≤75db |

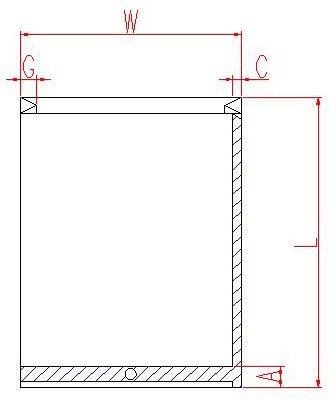

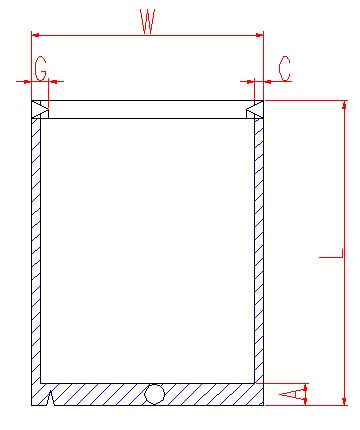

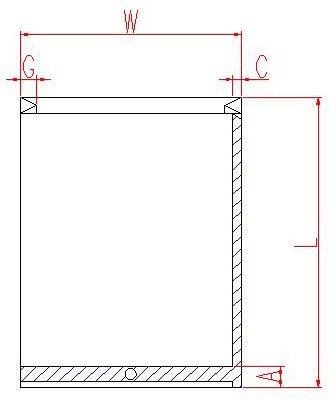

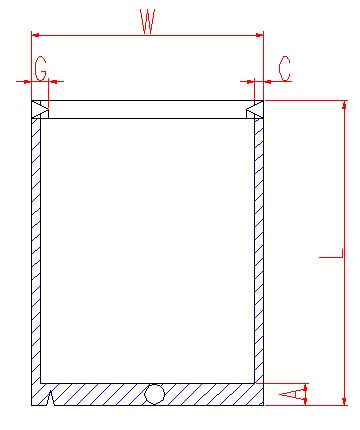

Three side sealing

Four side sealing

Four side sealing

Specification and relevant parameters

| Unwinding frame device |

| Structure |

ertical automatic error rectifying unwind structure |

| Tension control |

| Magnetic power brake braking |

| Initiative out feeding structure |

| Control mode |

floating type of dance roller displacing sensor controls speed of out feeding |

| Tightly fixed taper out feeding nip roller (with air expanding shaft ) |

| Error rectifying control (EPC) |

| Structure |

screw rod secondary adjustment, K shelf vertical lifting and falling |

| Drive |

Solid-state relay drives low speed synchronous motor |

| Transmission |

steel shaft coupling connection |

| Control type |

reflection electric transducer detection, independent control. |

| Tracking accuracy |

0.5mm |

| Adjustment range |

150mm |

| Opposite side up and down pieces |

| Structure |

roller’s single end spring pressing structure |

| Adjustment |

manual adjustment |

| A vertical sealing device

|

| Structure |

vertical displaying iron pressing, cooling assembly spring pressing structure |

| Drive |

main machine drives coupling rod of eccentric mechanism to do vertical movement |

| Quantity |

4 teams on thermal sealing, 4teams on cooling |

| Length |

700mm |

| B vertical zip device

|

| Structure |

vertical displaying iron pressing, cooling assembly spring pressing structure, bottom sealing knife; heat ironing holder pneumatic moves down when stopped machine. Automatic reset when machine started. |

| Drive |

main machine drives coupling rod of eccentric mechanism to do vertical movement |

| Quantity |

2 teams on thermal sealing, 2 teams on cooling |

| A horizontal sealing device

|

| Structure |

horizontal displaying iron press assembly spring structure, cooling assembly |

| Drive |

main machine drives coupling rod of eccentric mechanism to do vertical movement |

| Quantity |

three teams on thermal sealing, two teams on cooling |

| Length |

640mm |

| B Horizontal flattening device (heat flattening zip edge)

|

| Structure |

horizontal displaying iron press assembly spring structure |

| Drive |

same as horizontal sealing |

| Quantity |

2 sets on heat pressing |

| Film feeding Device

|

| Structure |

rubber roller pressing friction type |

| Drive |

imported fully digital runoff production servomechanism ( Panasonic, Japan ) |

| Transmission |

synchronous band and wheel |

| Control mode |

centralized PLC control, synchronous length fixing and middle tension control |

| Central tension

|

| Structure |

floating tension roll structure |

| Control mode |

centralized PLC control |

| Mechanism of control |

complementary trend of floating tension roller movement controls the center servo step length to achieve stop and beginning at the same time |

| Testing mode |

electromagnetism approaches switch ( NPN ) |

| Adjustment range of tension |

0.1-0.2mm (computer setting, automatic compensation) |

Main transmission device

|

| Structure |

crank rocker push and pulling coupling rod structure |

| Drive |

3KW Panasonic servo motor. |

| Transmission |

main transmission electric machinery band 1: 10 reducer |

| Control modality |

centralized PLC control |

| Running mode |

main motor running drives frame to do vertical movement |

| Automatic positioning device

|

| Testing mode |

tracking testing of reflection photoelectrical sensor |

| Testing accuracy |

0.01- 0.25mm |

| Integrative positioning accuracy |

≤0.5-1mm |

| Photoelectrical searching range |

±3mm |

| Rectifying equalizing range |

±3mm |

| Positioning rectifying wise |

servo tracks current equalizing, photoelectrical automatic movement rectify system |

| Temperature control setting

|

| Testing mode |

thermo couple test |

| Control mode |

centralized PLC control, PID adjustment, solid-state relay |

| Temperature setting range |

normal -360℃ |

| Temperature testing point |

central part electric heated |

| Double cutting knife (Moveable double cutting)

|

| Structure |

top cutting knife + adjustment equipment + fixed bottom cutting knife |

| Mode |

spring shear knife |

| Transmission |

main motor drive, eccentric mechanism up and down motion. |

| Adjustment |

horizontal move (two ends) |

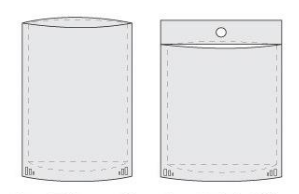

| Standing bag device |

| Automatic synchronous unwind system, free adjustment of unwind tension, tripod edge folding. |

| Automatic round holes pouching device and accurate positioning. |

| Automatic zip unwind device |

| Independent unwind single gearbox speed reducing motor feeding |

| Automatic photoelectric adjustment that ensure the synchronous speed with main motor |

| Punching device (adopts imported parts)

|

| Structure |

bowed supporting pneumatic engine leading main model impact structure |

| Control mode |

centralized PLC control |

| Drive |

Solid-state relay drives solenoid value |

| Quantity of punching stand |

basic two teams (rhombus) |

| Air cylinder |

Airtac, Taiwan |

| Welding knife device

|

| Horizontal: |

20mm*2 radix; 30mm*2 radix; 40mm*2 radix; 50mm*2 radix |

| Edge rewind

|

| Power supply |

three-phase 380V, ±10%, 50HZ five lines |

| Volume |

45KW |

| Air supply |

pressure ≥ 0.6Mpa |

| Cooling water |

3 L / min |

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for pinch bottom bag making machine Manufacturers – LQD-600C Three-side Sealing Automatic Bag Making Machine – UP Group, The product will supply to all over the world, such as: USA, moldova, British, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

By Kevin Ellyson from Marseille - 2018.06.21 17:11

By Kevin Ellyson from Marseille - 2018.06.21 17:11

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

By Laura from Morocco - 2018.09.29 17:23

By Laura from Morocco - 2018.09.29 17:23